When producing high-precision gears necessary for various mechanical applications, gear-finishing tools play a vital role. To ensure gear finishing tools manufacturers have optimal performance, durability, and quality, these tools’ manufacturers must exhibit particular characteristics. From cutting-edge material choices to creative plan strategies, the qualities of productive gear-completing device makers influence gear-producing processes’ proficiency. The essential factors that decide leading manufacturers in this competitive industry are examined in this introduction.

Technical Expertise and Industry Knowledge

Driving Producers that operate vehicles should always have a good understanding of gear technology and the challenges associated with gears production. This means getting to know spur, helical and planetary gears and some specific requirements with regard to finishing. A quality manufacturing tool is up to date on new occurrences and innovations in the sector to ensure that their tools meet the present manufacturing needs.

Superior Material Selection

The application of various materials in gear-finishing tools determines not only their performance but also their durability. Many manufacturers use high-grade steel, carbide, or specialized alloys that are very hard-wearing. These materials contribute to a longer tool’s life span, and given that gears are under a lot of pressure, these materials give improved finishes.

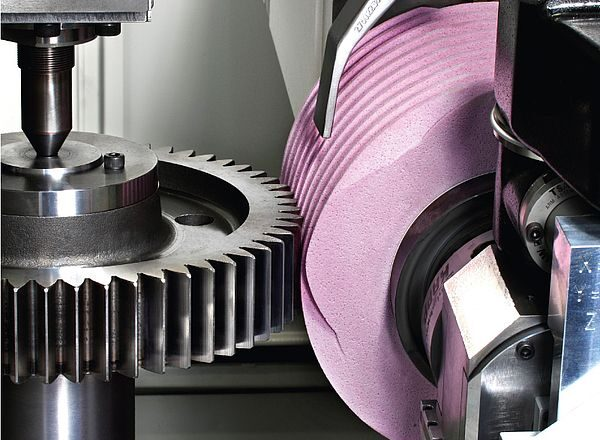

Advanced Manufacturing Processes

Most gear finishing processes require precision manufacturing to ensure gear accuracy is within the required tolerance levels. This often means that new-generation equipment, like CNC machines, has to be used to ensure that each tool is manufactured by the characteristics that were laid down for this tool. For the tools to meet the set dimensional precision and tolerance, there is the need to use quality control techniques such as CMM. Custom tools are used to create products that could be unique or completely different from usual market products but cannot be manufactured by regular tools due to close tolerance requirements.

Capabilities for Custom Tooling

The gear hob manufacturers in india should also ensure that their company provides options to provide tooling specific to the client in today’s competitive market. Due to the differences in the gears being produced, customization may entail altering the contour of the tool, the type of material, or even the surface finishing. This flexibility enhances the assembling system so that the clients are in a position to improve efficiency and quality.

Service and Support for the Customer

Exceptional customer service is essential for establishing long-term relationships with customers. To assist customers in efficiently using their tools, manufacturers ought to provide comprehensive technical support, including assistance with troubleshooting and product training. A responsive client care group can rapidly address requests and resolve issues, encouraging trust and reliability among clients.

Bottom line

For producers of gear finishing tools the requirements are perfect material procurement, appreciable product engineering, and product variety, proficiency in making custom tools, more emphasis on innovation, good customer services and eco-sensitivity. These features are useful for manufacturers who wish to overcome their rivals and adapt to new challenges of gear manufacturing industry. These qualities will remainder core in providing the quality and efficiency in the manufacturing of gears as innovation continues to advance forward.